Wankel Engines: The Rotary Revolution in Automotive Engineering

The Wankel engine, often referred to as the rotary engine, represents a unique approach to internal combustion engine design. Developed by German engineer Felix Wankel in the 1950s, this engine has captivated the automotive world with its innovative design and distinct advantages. Despite facing challenges over the years, the Wankel engine continues to be celebrated for its compact size, smooth operation, and high power-to-weight ratio. This article delves into the history, design, advantages, challenges, and future prospects of Wankel engines in the automotive industry.

The Genesis of the Wankel Engine

Felix Wankel, a self-taught engineer, envisioned an engine that differed fundamentally from the conventional piston engine. His goal was to create a simpler, more efficient design with fewer moving parts. In 1957, Wankel achieved his vision with the creation of the first working prototype of the rotary engine. The Wankel engine's unique triangular rotor design, which rotates within an epitrochoidal chamber, marked a significant departure from traditional reciprocating engines.

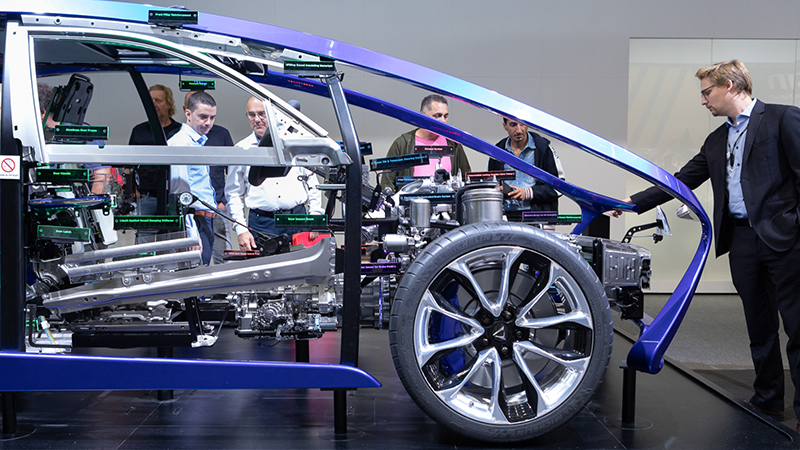

Design and Operation

The Wankel engine operates on the principle of rotary motion, using a triangular rotor that rotates within an oval-like chamber. This design has several key components:

Rotor: The rotor is a triangular, star-shaped component that rotates within the chamber. Each face of the rotor acts as a piston.

Epitrochoidal Chamber: The chamber has an epitrochoidal (oval-like) shape that accommodates the rotor's movement. This design ensures that the rotor maintains contact with the chamber walls, creating separate combustion chambers.

Eccentric Shaft: The rotor is mounted on an eccentric shaft that converts the rotor's rotational motion into the output shaft's motion.

The Wankel engine completes the four-stroke cycle (intake, compression, power, and exhaust) within one rotation of the rotor. As the rotor turns, the volume of the chambers changes, allowing the engine to draw in air-fuel mixture, compress it, ignite it, and expel exhaust gases.

Advantages of Wankel Engines

The Wankel engine offers several distinct advantages over traditional piston engines:

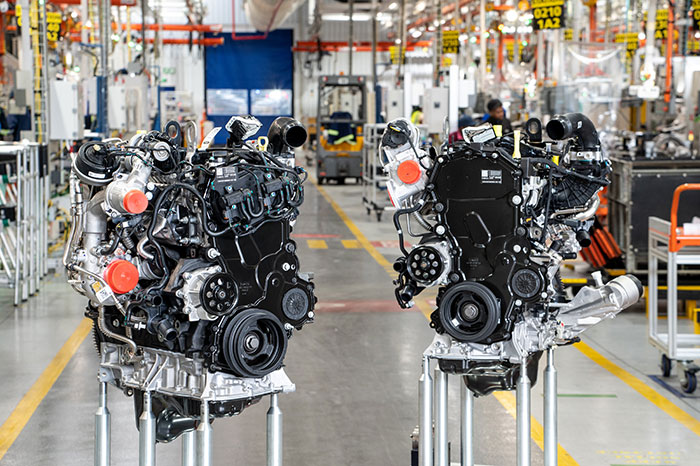

Compact Size and Light Weight: The rotary design allows for a more compact and lightweight engine, making it ideal for applications where space and weight are critical considerations.

Smooth Operation: The rotary motion of the Wankel engine results in less vibration compared to the reciprocating motion of piston engines. This smooth operation enhances driving comfort and reduces wear on engine components.

High Power-to-Weight Ratio: Due to its compact design and fewer moving parts, the Wankel engine can produce a high amount of power relative to its size and weight. This makes it particularly attractive for high-performance applications.

Fewer Moving Parts: The simplicity of the Wankel engine's design, with fewer moving parts and no valves, reduces mechanical complexity and potential points of failure. This can lead to increased reliability and easier maintenance.

Challenges and Criticisms

Despite its advantages, the Wankel engine has faced several challenges and criticisms:

Fuel Efficiency: Wankel engines

have historically struggled with fuel efficiency compared to traditional piston engines. The shape of the combustion chamber and the surface area of the rotor can lead to less efficient combustion, resulting in higher fuel consumption.

Emissions: Another significant challenge for Wankel engines has been their difficulty in meeting stringent emissions standards. The unique combustion process can lead to incomplete burning of the air-fuel mixture, producing higher levels of hydrocarbons and carbon monoxide.

Seal Durability: The apex seals, which are critical for maintaining the compression within the combustion chamber, can wear out more quickly than the components in a piston engine. This wear can lead to decreased performance and increased maintenance costs.

Thermal Management: The Wankel engine's design can lead to uneven heating, which poses challenges for thermal management. Efficiently dissipating heat and preventing hot spots is more complex compared to traditional engines.

Notable Applications and Developments

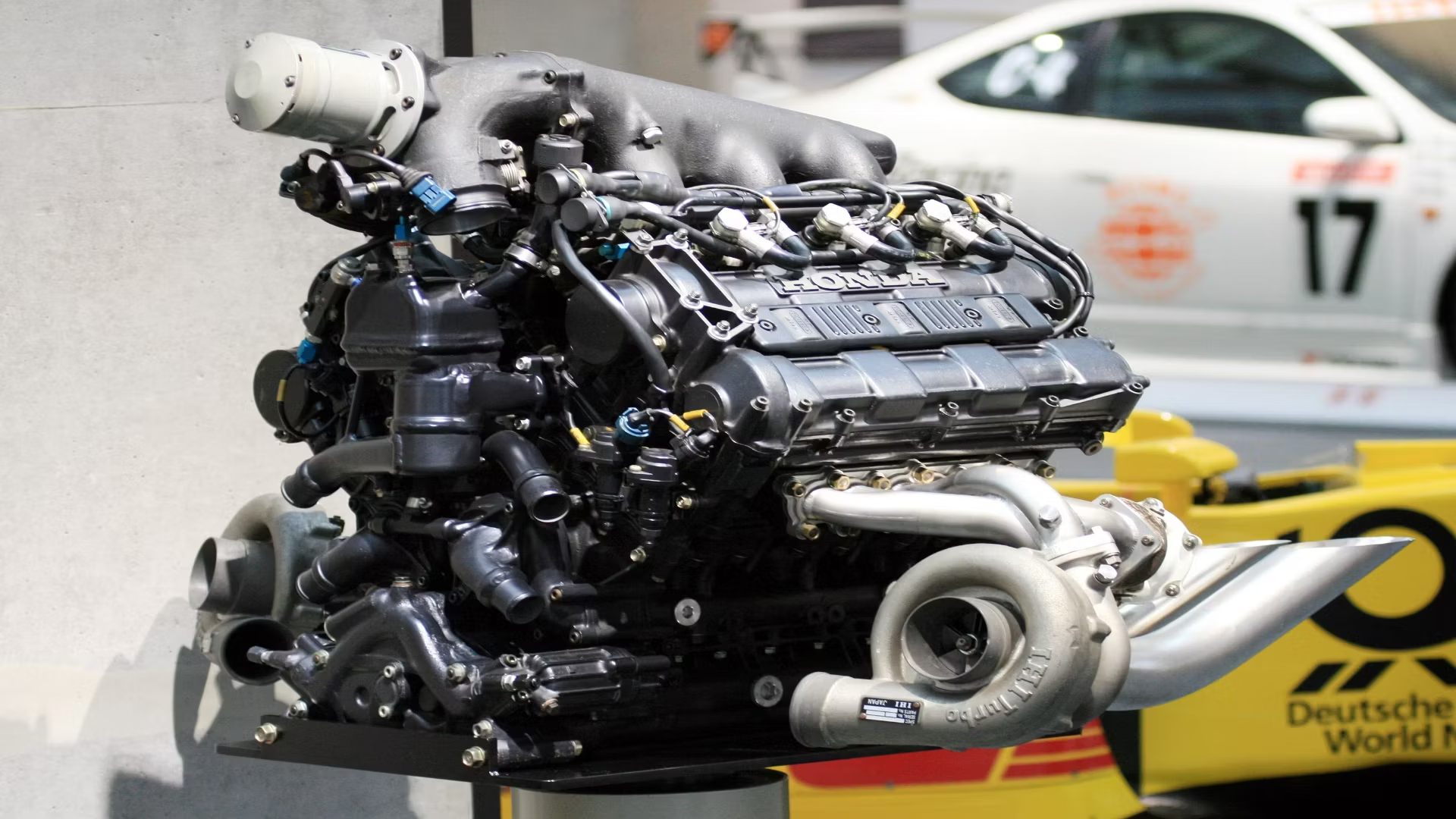

Despite these challenges, Wankel engines have found a niche in certain applications where their advantages can be fully utilized. One of the most famous adopters of the Wankel engine is Mazda. The Japanese automaker has a long history with rotary engines, starting with the Mazda Cosmo in the 1960s and continuing through the RX series, including the iconic RX-7 and RX-8 sports cars. Mazda's commitment to the Wankel engine culminated in the 787B, which won the 1991 24 Hours of Le Mans, marking the only victory for a rotary-powered car in the history of the race.

The Future of Wankel Engines

In recent years, there has been renewed interest in the Wankel engine, driven by advancements in materials and technology. These developments aim to address the traditional shortcomings of the rotary design, particularly in the areas of fuel efficiency, emissions, and durability.

Hybrid Applications: One promising area for the Wankel engine is in hybrid powertrains. The compact size and high power output of the rotary engine make it well-suited as a range extender in electric vehicles (EVs). By using the Wankel engine to generate electricity for the battery, manufacturers can create hybrid systems that benefit from the rotary engine’s advantages while mitigating its fuel efficiency and emissions issues.

Improved Materials and Seals: Advances in materials science have led to the development of more durable and heat-resistant materials for apex seals and other critical components. These improvements can enhance the longevity and performance of Wankel engines.

Alternative Fuels: The exploration of alternative fuels, such as hydrogen, presents an exciting opportunity for the Wankel engine. Hydrogen combustion can address some of the emissions concerns associated with traditional gasoline, making the rotary engine a cleaner and more environmentally friendly option.

Automotive and Beyond: While automotive applications remain a primary focus, Wankel engines are also being explored for use in other fields, such as aviation, marine, and even portable power generation. The unique characteristics of the rotary engine make it versatile and adaptable to various industries.

Conclusion

The Wankel engine stands as a testament to innovative engineering and the quest for alternative approaches to internal combustion. Despite facing significant challenges over the decades, the rotary engine continues to capture the imagination of engineers and enthusiasts alike. Its unique advantages, such as compact size, smooth operation, and high power-to-weight ratio, offer compelling reasons for ongoing research and development.

As advancements in technology continue to address the historical shortcomings of the Wankel engine, its potential applications expand. From hybrid vehicles to alternative fuels, the future of the Wankel engine looks promising, with the possibility of a renaissance driven by new materials, better efficiency, and environmental sustainability.

In the ever-evolving landscape of automotive engineering, the Wankel engine remains a fascinating chapter, illustrating the creativity and persistence required to push the boundaries of what is possible. As we look ahead, the rotary engine may yet find its place in a new generation of vehicles, proving that innovation can turn even the most unconventional ideas into revolutionary solutions.