The Vital Role of Engine Oil Pumps in Automotive Performance and Longevity

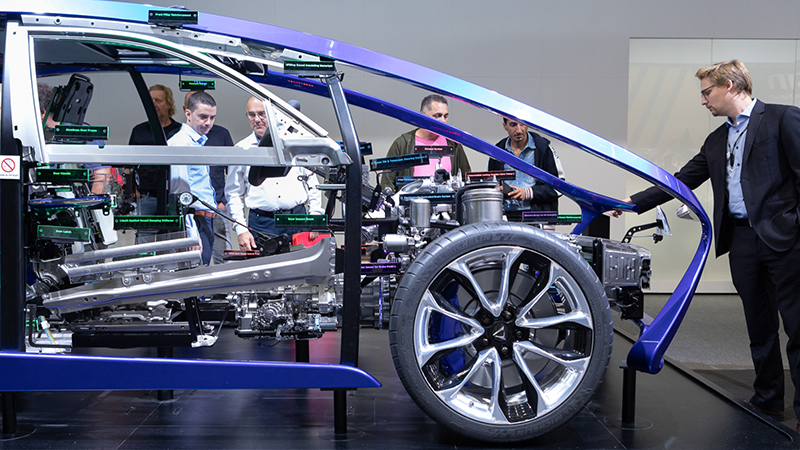

In the intricate ecosystem of an internal combustion engine, the oil pump plays an indispensable role, ensuring that all moving parts are adequately lubricated. This small but mighty component is crucial for maintaining engine performance, reducing wear and tear, and ultimately extending the life of the engine. Understanding the importance of engine oil pumps and how they work is essential for anyone interested in automotive mechanics or engine maintenance.

How Engine Oil Pumps Work

An engine oil pump's primary function is to circulate engine oil under pressure to the rotating bearings, sliding pistons, and the camshaft of the engine. This process is vital for several reasons:

Lubrication: The oil reduces friction between moving parts, which can generate significant heat and lead to wear and tear. Proper lubrication ensures that the engine runs smoothly.

Cooling: The oil helps dissipate heat away from critical engine parts, preventing overheating and maintaining optimal engine temperature.

Cleaning: Circulating oil helps trap dirt, debris, and microscopic metal particles, carrying them away from the engine parts to the oil filter.

Hydraulic Pressure: Oil pumps provide the necessary pressure to operate hydraulic components such as valve lifters and timing chain tensioners.

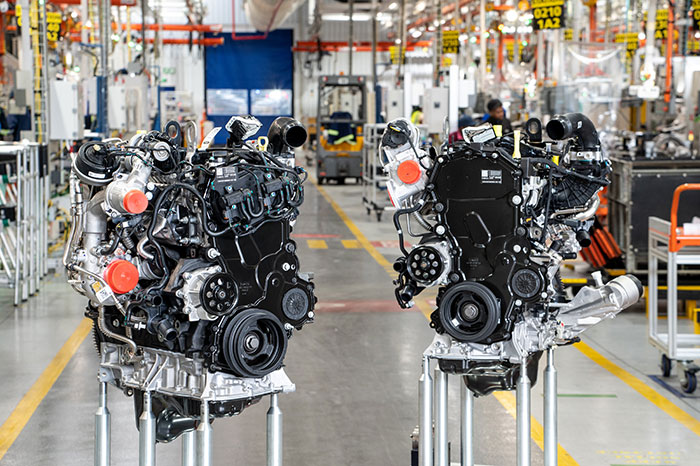

The engine oil pump is typically driven by the crankshaft, ensuring that oil circulation begins as soon as the engine starts. There are several types of oil pumps, including gear pumps, rotor pumps, and vane pumps, each with specific advantages and suitable applications.

Types of Engine Oil Pumps

Gear Pumps: The most common type, gear pumps use interlocking gears to pump oil. They are reliable and efficient, capable of handling high pressure and providing a steady flow of oil.

Rotor Pumps: Also known as gerotor pumps, these use a gear-within-a-gear mechanism. Rotor pumps are known for their compact size and smooth operation, making them ideal for modern, high-performance engines.

Vane Pumps: These pumps use a series of vanes that move in and out of slots to pump oil. Vane pumps can handle a wide range of oil viscosities and provide consistent pressure, although they are less common in automotive applications compared to gear and rotor pumps.

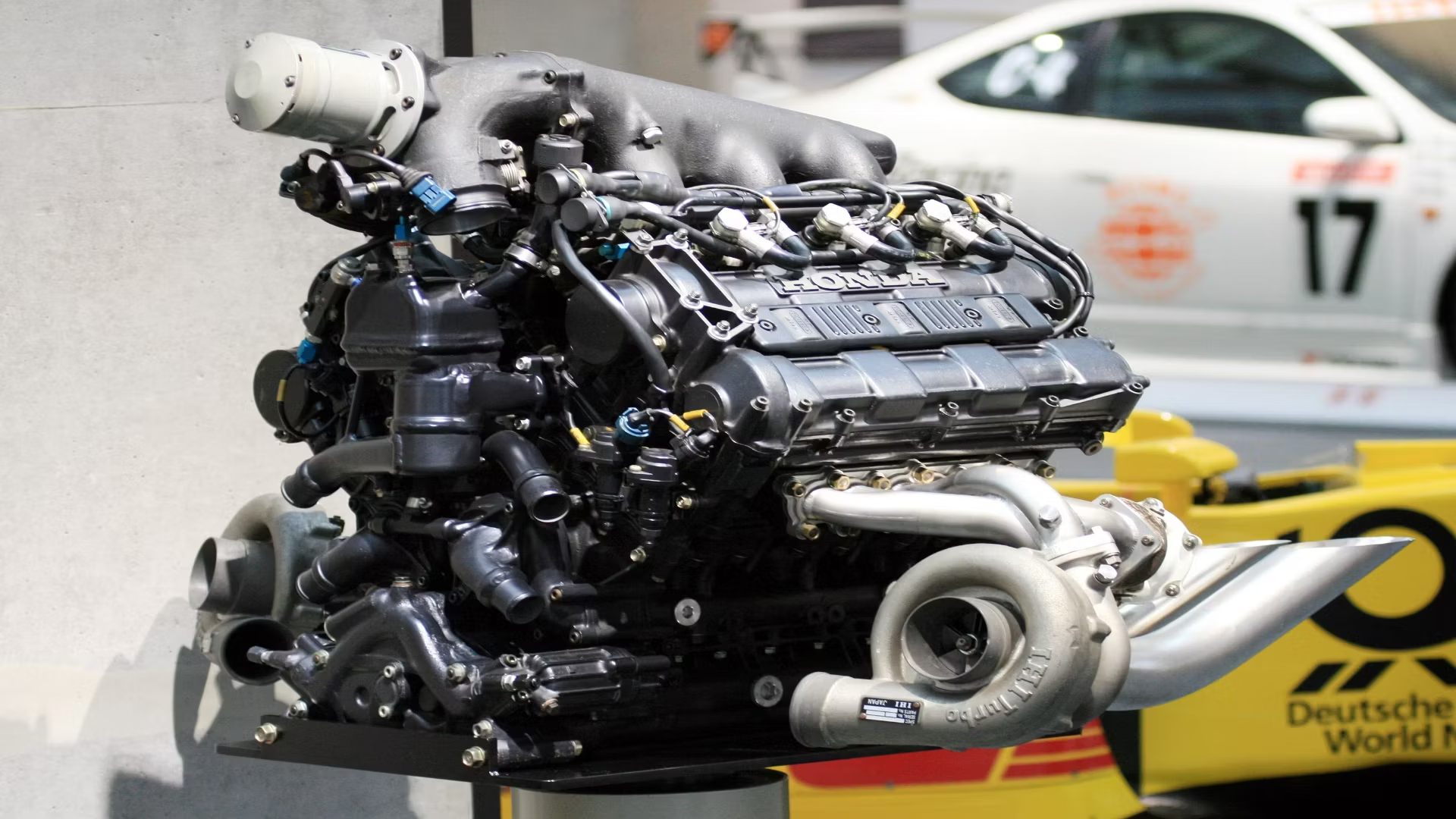

Importance of Oil Pumps in Engine Performance

The performance of an engine oil pump directly impacts the overall efficiency and lifespan of the engine. A well-functioning oil pump ensures:

Optimal Lubrication: Continuous and adequate lubrication prevents metal-to-metal contact between moving parts, reducing wear and extending the engine's lifespan.

Temperature Control: By circulating oil, the pump helps dissipate heat generated by the engine, maintaining a stable operating temperature and preventing overheating.

Engine Cleanliness: Regular oil circulation helps remove contaminants and microscopic debris, which are then trapped by the oil filter, keeping the engine clean and reducing the risk of damage.

Consistent Hydraulic Pressure: Many modern engines rely on hydraulic pressure for various functions, including valve operation and timing adjustments. A reliable oil pump ensures that these systems work correctly.

Common Issues with Oil Pumps

Despite their durability, oil pumps can experience problems that may compromise engine performance. Common issues include:

Wear and Tear: Over time, the moving parts within an oil pump can wear down, reducing efficiency and causing a drop in oil pressure.

Contamination: Dirt, debris, or sludge in the oil can damage the pump's internal components, leading to failure.

Oil Leaks: Leaks in the oil pump or related components can lead to insufficient oil pressure, which can severely damage the engine.

Pump Failure: Complete failure of the oil pump is rare but can occur, leading to a catastrophic loss of oil pressure and potential engine damage.

Maintenance and Care

Regular maintenance is key to ensuring the longevity and performance of an engine oil pump. Here are some essential maintenance tips:

Regular Oil Changes: Frequent oil changes ensure that the oil remains clean and free from contaminants that could damage the pump and engine.

Use Quality Oil: High-quality engine oil with the correct viscosity rating for your vehicle helps maintain proper lubrication and pump performance.

Monitor Oil Levels: Regularly check the oil level to ensure there is enough oil for the pump to circulate.

Inspect for Leaks: Periodically inspect the engine for oil leaks, which could indicate a problem with the pump or related components.

Listen for Unusual Noises: Unusual noises from the engine, such as knocking or ticking, could indicate an oil pump issue and should be investigated promptly.

Conclusion

The engine oil pump is a crucial component that ensures the smooth operation and longevity of an internal combustion engine. By maintaining proper lubrication, cooling, and cleanliness, the oil pump plays a vital role in engine performance. Regular maintenance and attention to oil quality and levels can help prevent issues and extend the life of the oil pump and the engine it serves. Understanding the importance of this often-overlooked component can lead to better engine care and more reliable vehicle performance.