Revolutionizing Truck Efficiency: The Role of Oxygen Sensors in Commercial Vehicles

In the intricate ecosystem of commercial vehicles, efficiency, performance, and environmental responsibility are paramount. Among the array of technologies driving these vehicles forward, oxygen sensors stand out as unsung heroes, playing a crucial role in optimizing engine performance, reducing emissions, and enhancing fuel efficiency. In this article, we delve into the significance of oxygen sensors in commercial trucks and how they are revolutionizing the way these vehicles operate on the road.

Understanding Oxygen Sensors

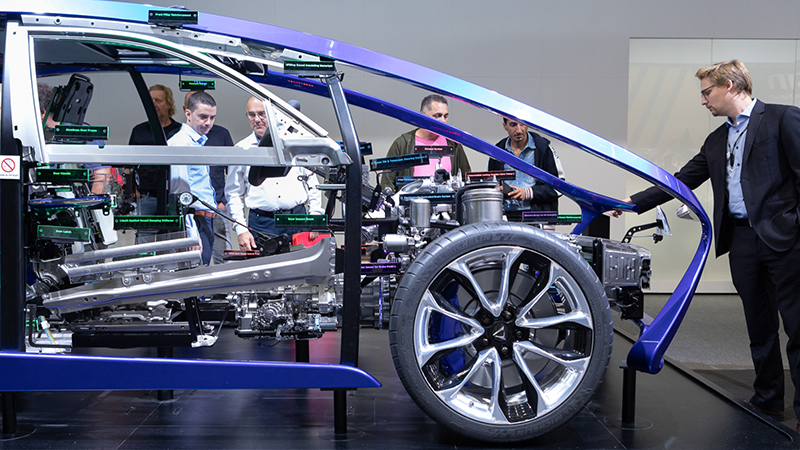

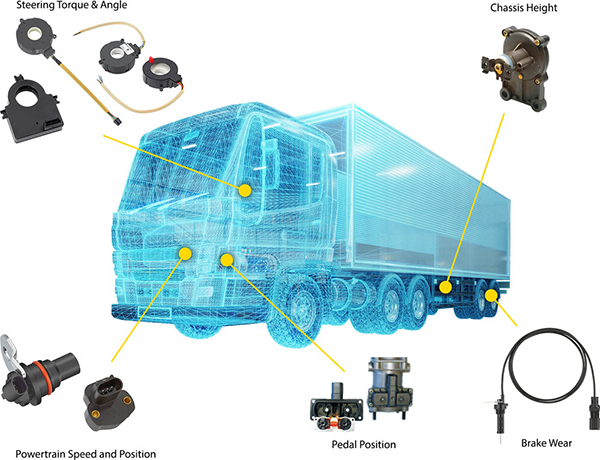

Oxygen sensors, also known as O2 sensors, are small but mighty components nestled within the exhaust system of commercial trucks. Their primary function is to monitor the level of oxygen in the exhaust gases emitted by the engine. This data is then relayed to the vehicle's engine control unit (ECU), which adjusts the air-fuel mixture to optimize combustion efficiency.

Optimizing Combustion Efficiency

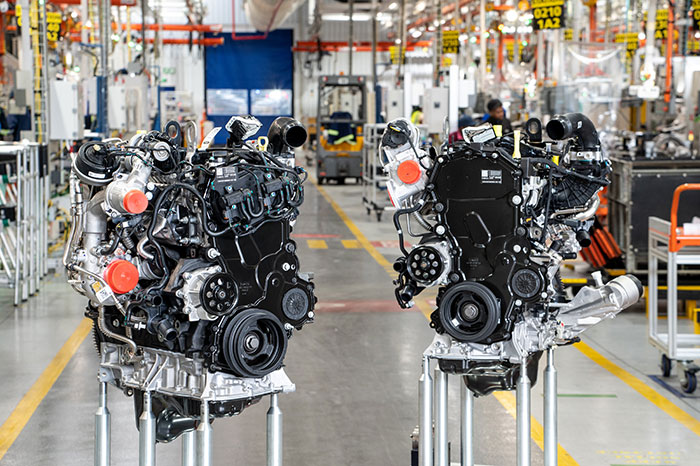

One of the key benefits of oxygen sensors in commercial trucks is their ability to optimize combustion efficiency. By continuously monitoring oxygen levels in the exhaust gases, oxygen sensors enable the ECU to precisely regulate the air-fuel mixture fed into the engine. This ensures that the engine burns fuel more efficiently, resulting in improved fuel economy and reduced emissions.

Reducing Harmful Emissions

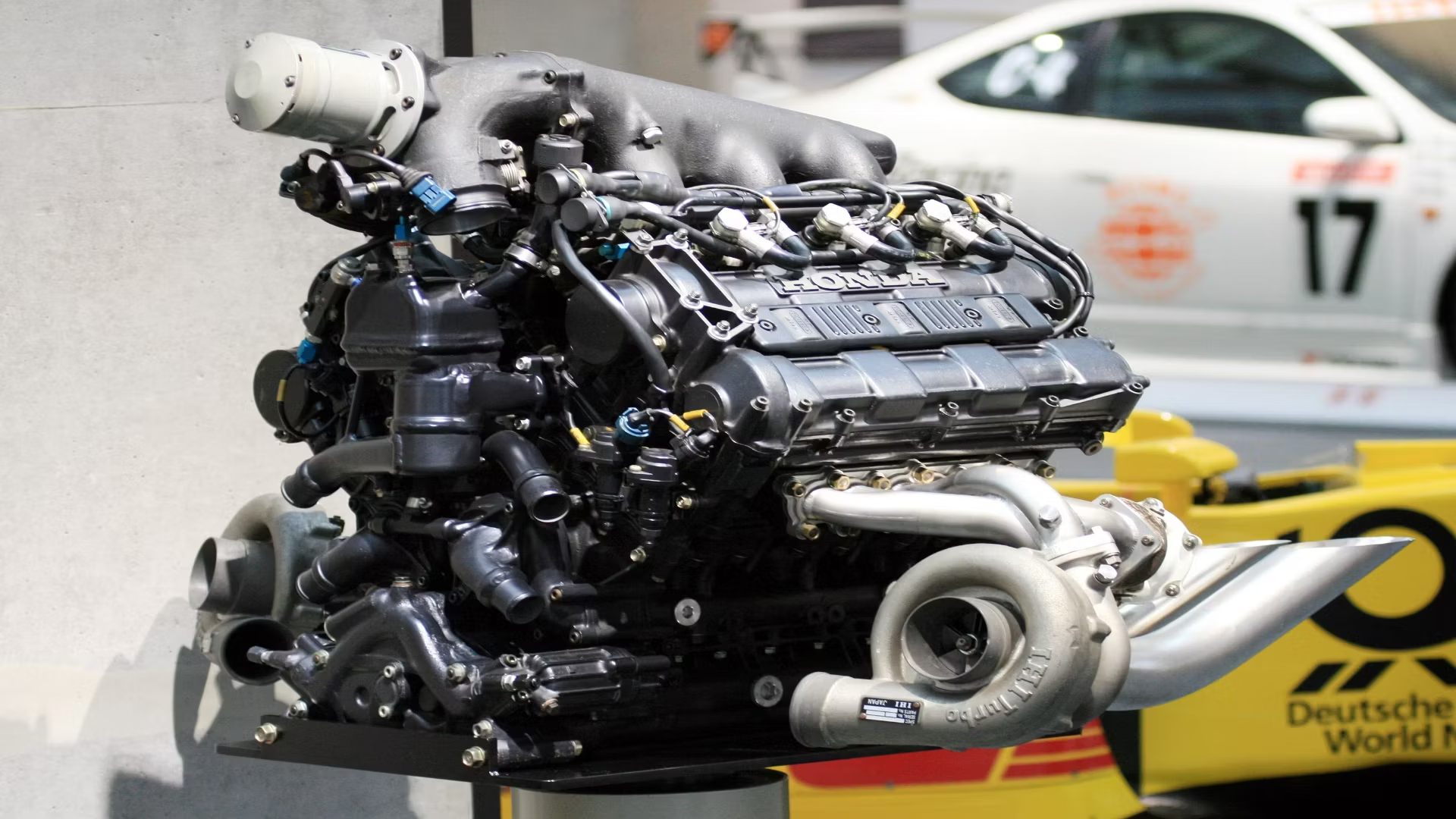

In addition to enhancing fuel efficiency, oxygen sensors also play a crucial role in reducing harmful emissions emitted by commercial trucks. By maintaining the optimal air-fuel ratio, oxygen sensors help minimize the production of pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and hydrocarbons (HC). This not only helps comply with stringent emissions regulations but also contributes to cleaner air and a healthier environment.

Enhancing Performance and Reliability

Beyond their environmental benefits, oxygen sensors also contribute to the overall performance and reliability of commercial trucks. By ensuring that the engine operates at its peak efficiency, oxygen sensors help maximize power output and torque, allowing trucks to tackle demanding tasks with ease. Additionally, by preventing engine misfires and other performance issues, oxygen sensors help extend the lifespan of critical engine components, reducing maintenance costs and downtime for truck operators.

The Role of Komotashi

At the forefront of innovation in automotive components is Komotashi, a leading manufacturer of oxygen sensors and other critical engine components for commercial vehicles. With a focus on quality, reliability, and performance, Komotashi's oxygen sensors are trusted by truck manufacturers and operators worldwide to deliver consistent results in even the most demanding operating conditions.

Komotashi's oxygen sensors are engineered to meet the rigorous standards of the automotive industry, incorporating advanced materials, precision manufacturing techniques, and cutting-edge sensor technology. Designed for durability and accuracy, Komotashi's sensors provide real-time data to the vehicle's ECU, allowing for precise control of the engine's air-fuel mixture and optimizing performance and efficiency.

Looking Ahead

As the automotive industry continues to evolve, the role of oxygen sensors in commercial trucks will only grow in importance. With a focus on improving efficiency, reducing emissions, and enhancing performance, oxygen sensors will remain indispensable components in the quest for cleaner, more sustainable transportation solutions. And with companies like Komotashi leading the way in innovation and quality, the future of oxygen sensors in commercial trucks looks brighter than ever.