Komotashi's Precision Craftsmanship: Revolutionizing Cylinder Head Production

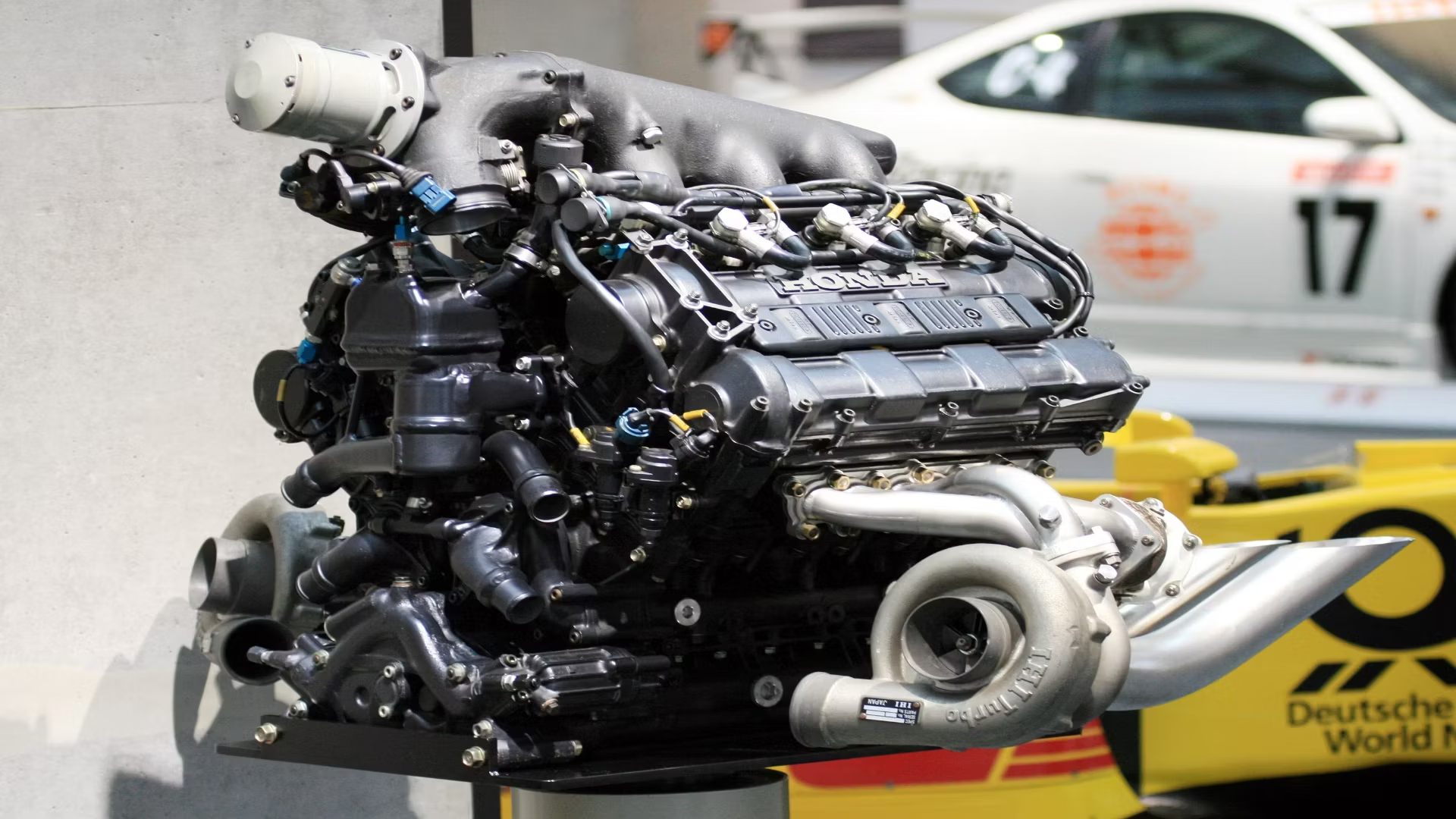

In the intricate world of automotive manufacturing, few components are as critical to engine performance as the cylinder head. Serving as the interface between the engine block and the combustion chamber, the cylinder head plays a pivotal role in ensuring efficient combustion, optimal airflow, and overall engine reliability. At the forefront of cylinder head production stands Komotashi, a global leader in automotive components, renowned for its precision craftsmanship and innovative engineering. In this article, we delve into Komotashi's expertise in cylinder head production and how it is revolutionizing the automotive industry.

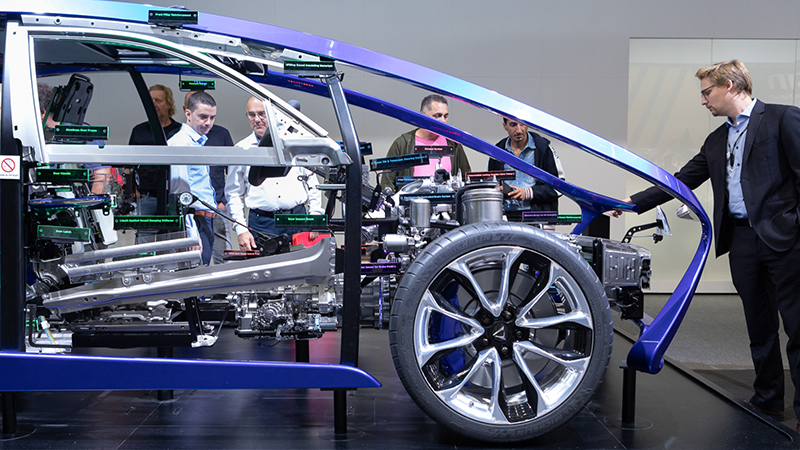

The Heart of the Engine: Understanding Cylinder Heads

The cylinder head is a complex component that houses the intake and exhaust valves, spark plugs, and fuel injectors, among other critical elements. Its primary function is to seal the combustion chamber, facilitate the intake of air and fuel, and expel exhaust gases after combustion. As such, the design and quality of the cylinder head are crucial factors in determining engine performance, efficiency, and longevity.

Komotashi's Commitment to Excellence

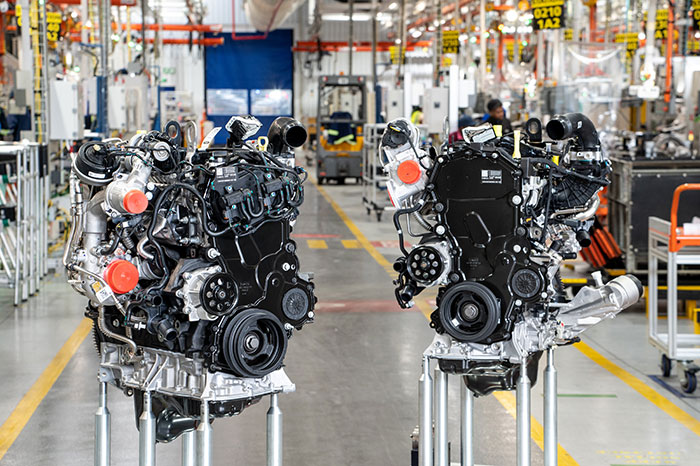

At Komotashi, precision craftsmanship is at the core of everything they do, and cylinder head production is no exception. Leveraging advanced manufacturing techniques, state-of-the-art machinery, and a team of skilled engineers and technicians, Komotashi produces cylinder heads that meet the highest standards of quality, reliability, and performance.

From design and prototyping to casting, machining, and assembly, every step of Komotashi's cylinder head production process is meticulously controlled and monitored to ensure consistency and accuracy. This attention to detail allows Komotashi to deliver cylinder heads that not only meet but exceed the stringent requirements of automotive manufacturers and customers worldwide.

Advanced Materials and Manufacturing Techniques

Central to Komotashi's cylinder head production is the use of advanced materials and manufacturing techniques. By employing high-strength alloys, such as aluminum and cast iron, Komotashi is able to produce cylinder heads that are lightweight, durable, and corrosion-resistant, without compromising on strength or performance.

Additionally, Komotashi utilizes state-of-the-art machining technologies, including computer numerical control (CNC) machining and robotic automation, to achieve precise tolerances and surface finishes. This level of precision ensures optimal sealing, airflow, and combustion efficiency, resulting in engines that deliver exceptional performance and fuel economy.

Innovative Design and Engineering

Komotashi's expertise in cylinder head production is further exemplified by its innovative design and engineering capabilities. With a focus on continuous improvement and innovation, Komotashi collaborates closely with automotive manufacturers to develop cylinder heads that are tailored to specific engine designs, performance requirements, and emissions standards.

Through advanced computational fluid dynamics (CFD) simulations and finite element analysis (FEA), Komotashi optimizes the design of its cylinder heads for maximum airflow, combustion efficiency, and thermal management. This iterative design process allows Komotashi to achieve superior performance and reliability while minimizing weight and complexity.

Driving Automotive Excellence

In conclusion, Komotashi's commitment to precision craftsmanship, advanced materials, and innovative engineering is revolutionizing the production of cylinder heads and setting new standards of excellence in the automotive industry. With a relentless focus on quality, reliability, and performance, Komotashi is driving automotive excellence and shaping the future of engine technology. As the automotive industry continues to evolve, Komotashi remains at the forefront of innovation, delivering cylinder heads that power vehicles of today and tomorrow with efficiency, reliability, and performance.