Komotashi: Revolutionizing Engine Performance with High-Quality Connecting Rods for Cars and Trucks

Komotashi, a prominent player in the automotive industry, continues to lead the market with its innovative production of connecting rods (bielle) for both car and truck engines. Renowned for its commitment to excellence, Komotashi's state-of-the-art manufacturing processes and advanced technologies ensure that their connecting rods set the standard for performance, reliability, and durability in the industry.

Pioneering Production Techniques

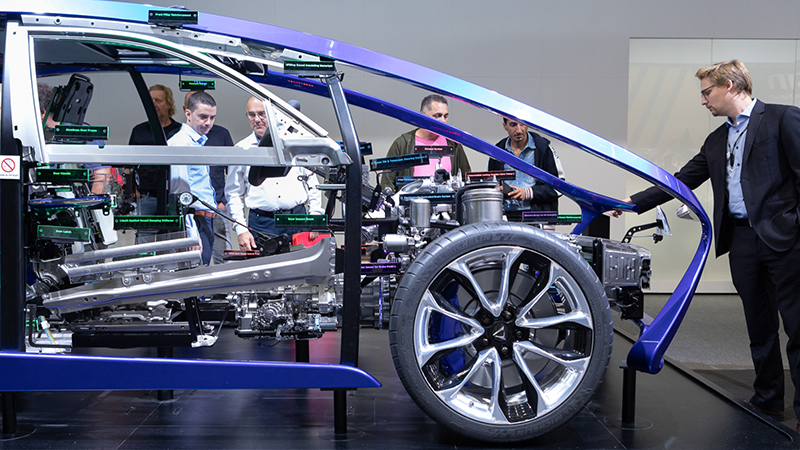

Since its inception, Komotashi has been dedicated to advancing manufacturing techniques to produce the highest quality engine components. The company's production of connecting rods, a critical part of the internal combustion engine, showcases this dedication. Connecting rods transfer the force from the piston to the crankshaft, converting the piston's linear motion into rotational motion. This critical function demands extreme precision and strength, which Komotashi achieves through cutting-edge production methods.

Advanced Materials and Engineering

One of the key factors that distinguish Komotashi's connecting rods is the use of advanced materials. The company employs high-grade steel alloys, which offer exceptional tensile strength and fatigue resistance. These materials are meticulously selected to withstand the high-pressure environments and extreme temperatures typical in both car and truck engines.

Moreover, Komotashi integrates sophisticated engineering techniques such as finite element analysis (FEA) and computer-aided design (CAD) to optimize the shape and structure of their connecting rods. These technologies allow engineers to simulate various stress scenarios and optimize the rods for maximum performance and durability, ensuring they can handle the rigorous demands of modern engines.

Precision Manufacturing

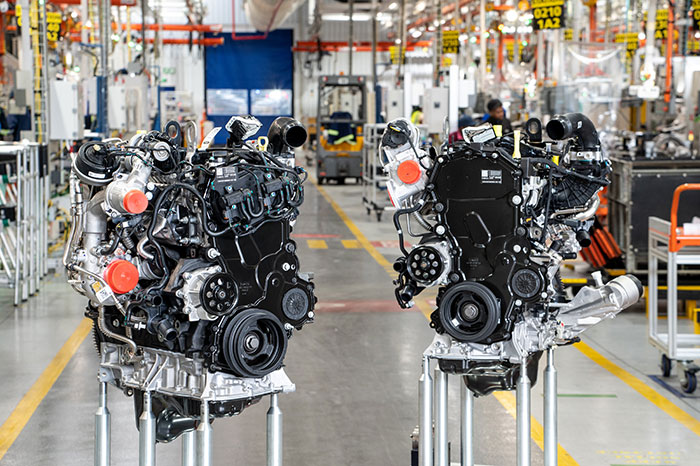

Komotashi’s manufacturing facilities are equipped with the latest machinery and technology, enabling the production of connecting rods with unmatched precision. The production process includes several stages:

Forging: The raw steel alloy is first forged into the basic shape of the connecting rod. This process enhances the material's strength and grain structure.

Machining: Advanced CNC machines are used to refine the rod’s dimensions to exact specifications. This step is crucial for ensuring the rod fits perfectly within the engine and operates efficiently.

Heat Treatment: The connecting rods undergo heat treatment processes to enhance their mechanical properties, such as hardness and toughness.

Surface Treatment: Various surface treatments, such as shot peening and coating, are applied to improve fatigue resistance and reduce friction.

Each connecting rod produced by Komotashi undergoes rigorous quality control checks at every stage of the manufacturing process. This meticulous attention to detail ensures that each rod meets the company's high standards for quality and performance.

Customization and Versatility

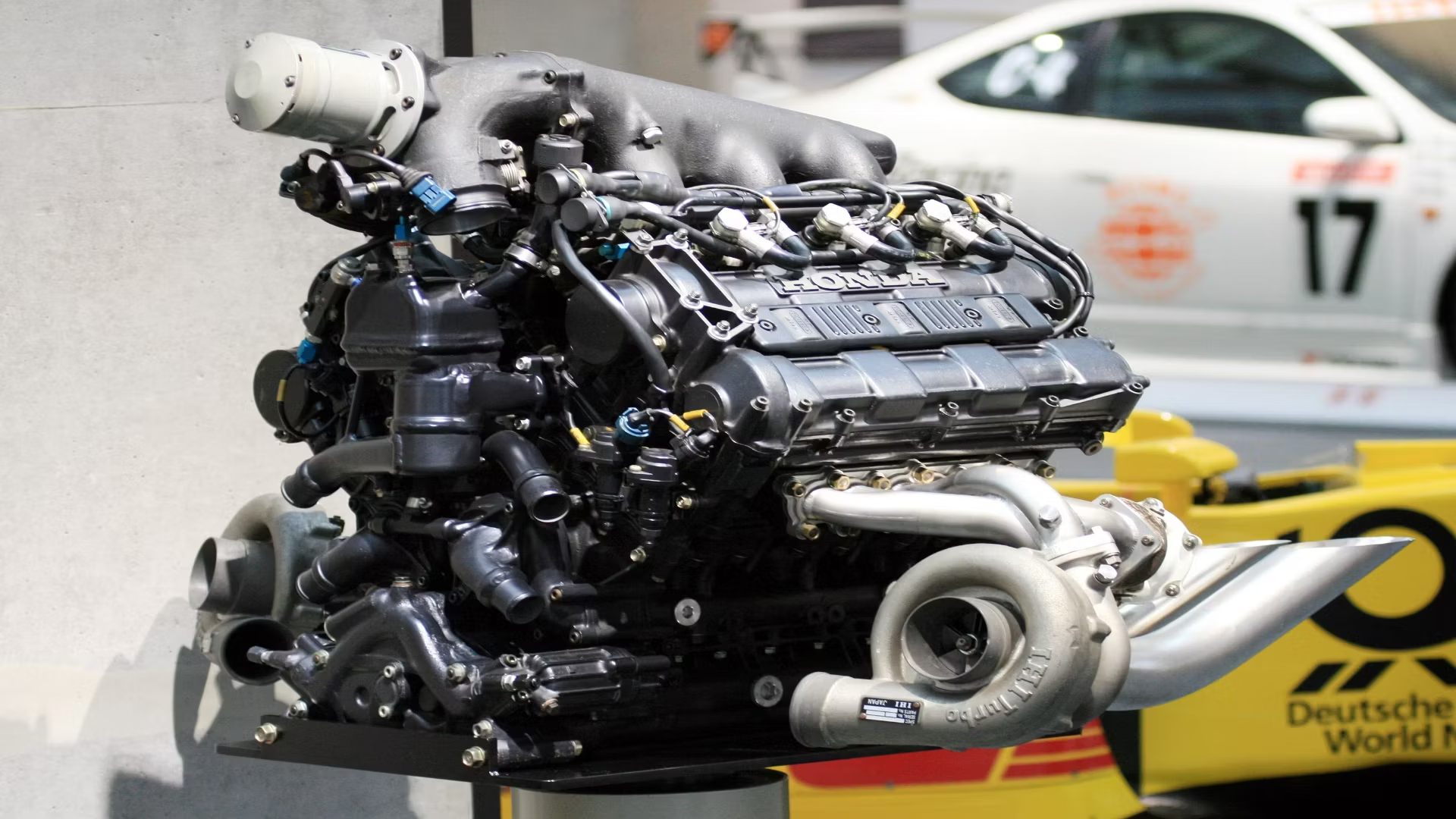

Komotashi understands that different engines require different specifications, and as such, the company offers a range of customizable options for their connecting rods. Whether for high-performance sports cars, heavy-duty trucks, or standard passenger vehicles, Komotashi provides connecting rods tailored to meet specific performance and durability requirements.

For high-performance applications, such as racing or off-road vehicles, Komotashi offers lightweight, high-strength rods designed to handle extreme RPMs and power outputs. These rods are meticulously engineered to reduce reciprocating mass, which improves engine response and efficiency.

Environmental and Economic Impact

In addition to performance, Komotashi is committed to sustainability and minimizing the environmental impact of their production processes. The company employs eco-friendly manufacturing techniques, such as using recycled materials and implementing energy-efficient processes. This approach not only reduces their carbon footprint but also lowers production costs, savings that Komotashi passes on to their customers.

Innovation and Future Prospects

Komotashi continues to push the boundaries of innovation in the production of connecting rods. The company is investing heavily in research and development to explore new materials and manufacturing techniques that will further enhance the performance and durability of their products. One area of focus is the integration of composite materials, which could offer even greater strength-to-weight ratios than traditional steel alloys.

Furthermore, Komotashi is exploring the potential of additive manufacturing (3D printing) for producing connecting rods. This cutting-edge technology allows for complex geometries and lightweight structures that are not feasible with traditional manufacturing methods. By adopting such innovative approaches, Komotashi aims to remain at the forefront of the automotive industry, continually improving the performance and efficiency of their engine components.

Conclusion

Komotashi's production of high-quality connecting rods for car and truck engines exemplifies their commitment to excellence and innovation. Through the use of advanced materials, precision manufacturing techniques, and rigorous quality control, the company delivers products that enhance engine performance and reliability. As Komotashi continues to invest in research and development, the future looks promising for even more groundbreaking advancements in engine technology. For automotive manufacturers and enthusiasts alike, Komotashi’s connecting rods represent the pinnacle of engineering prowess and a key component in the quest for superior engine performance.