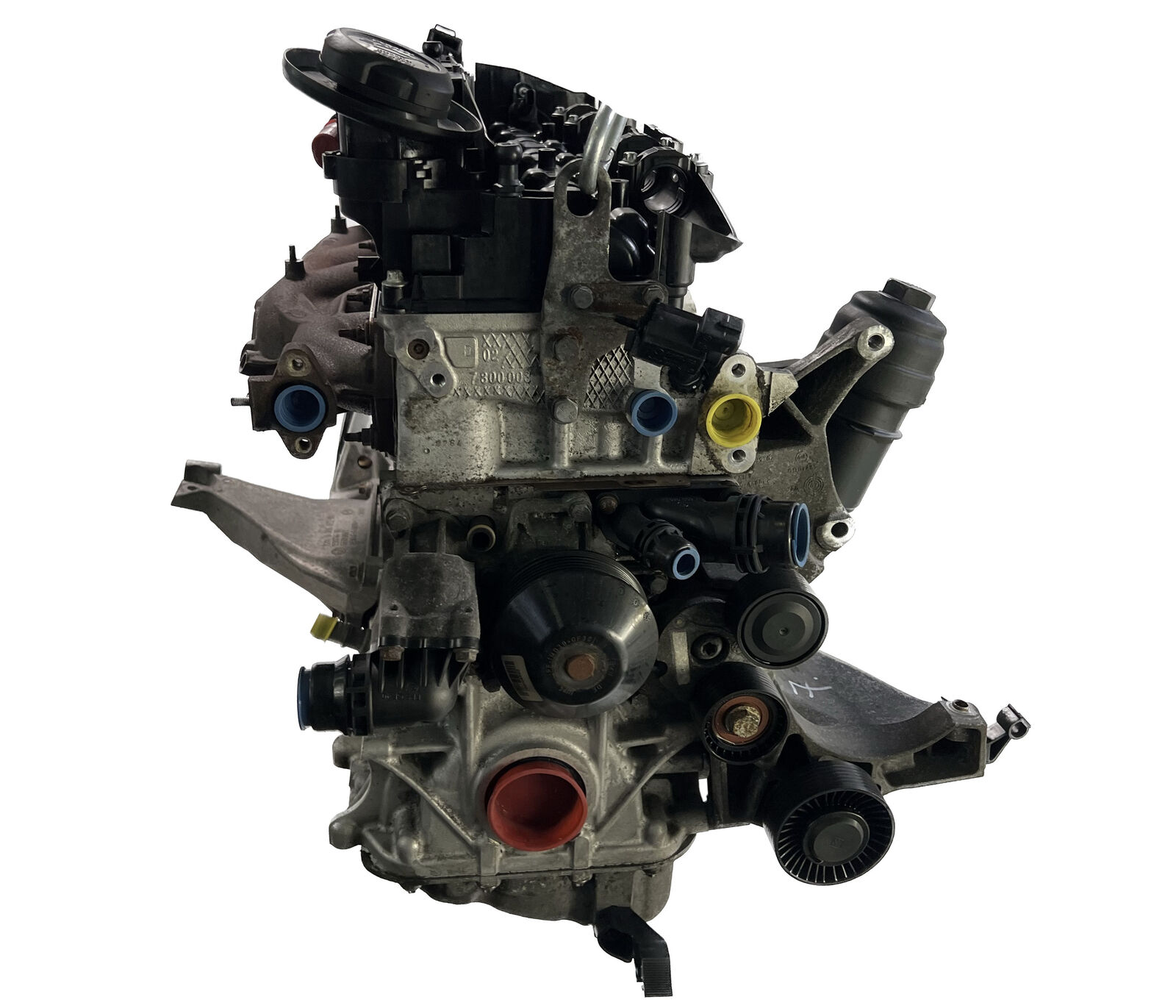

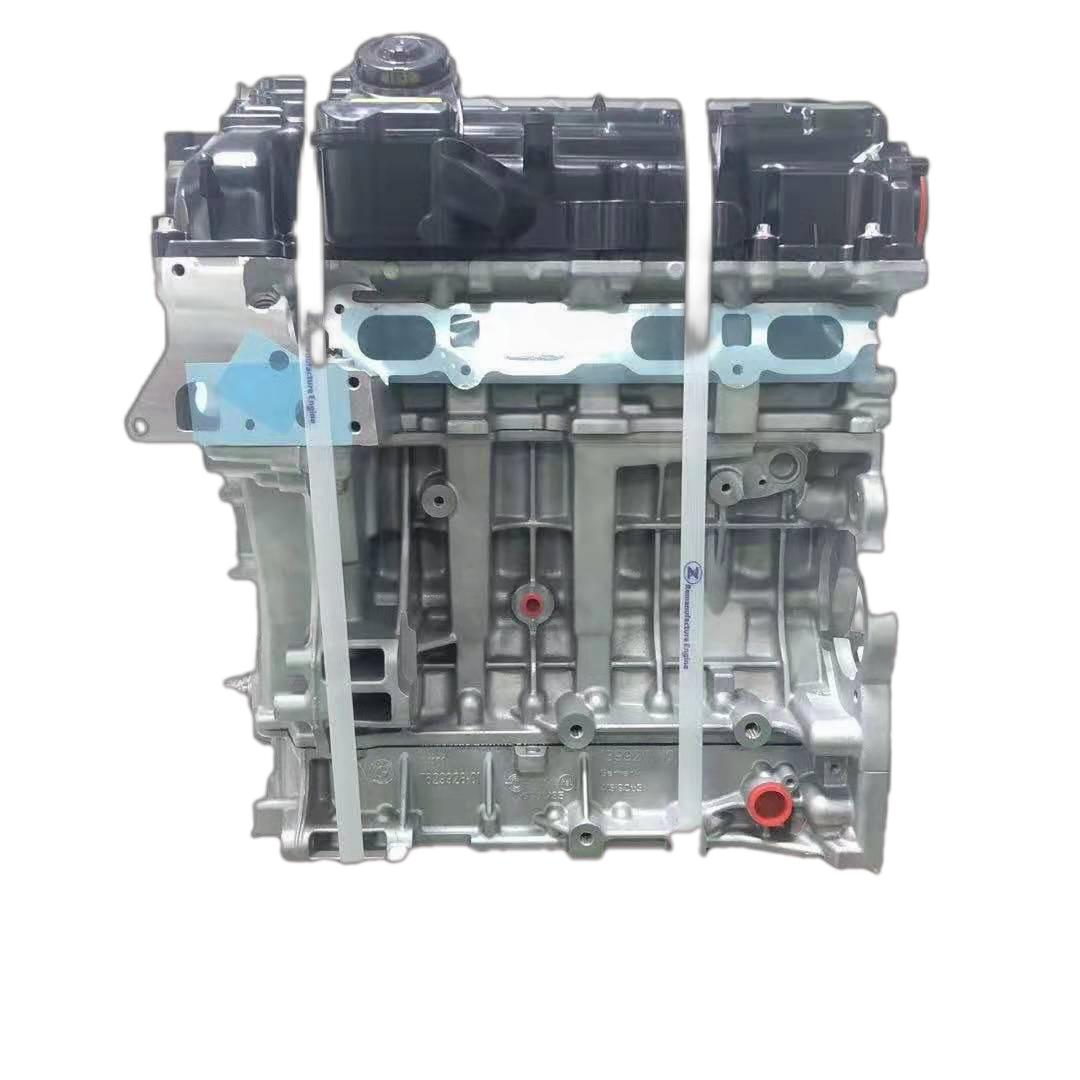

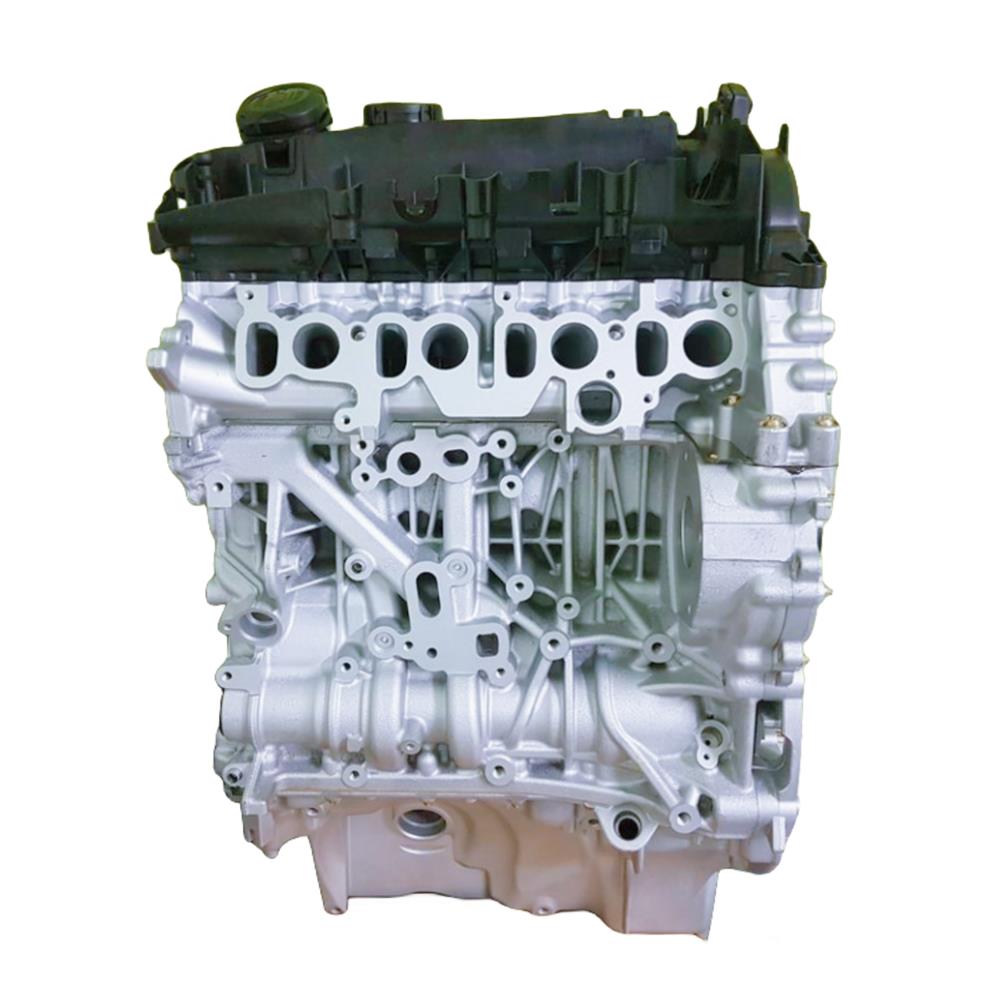

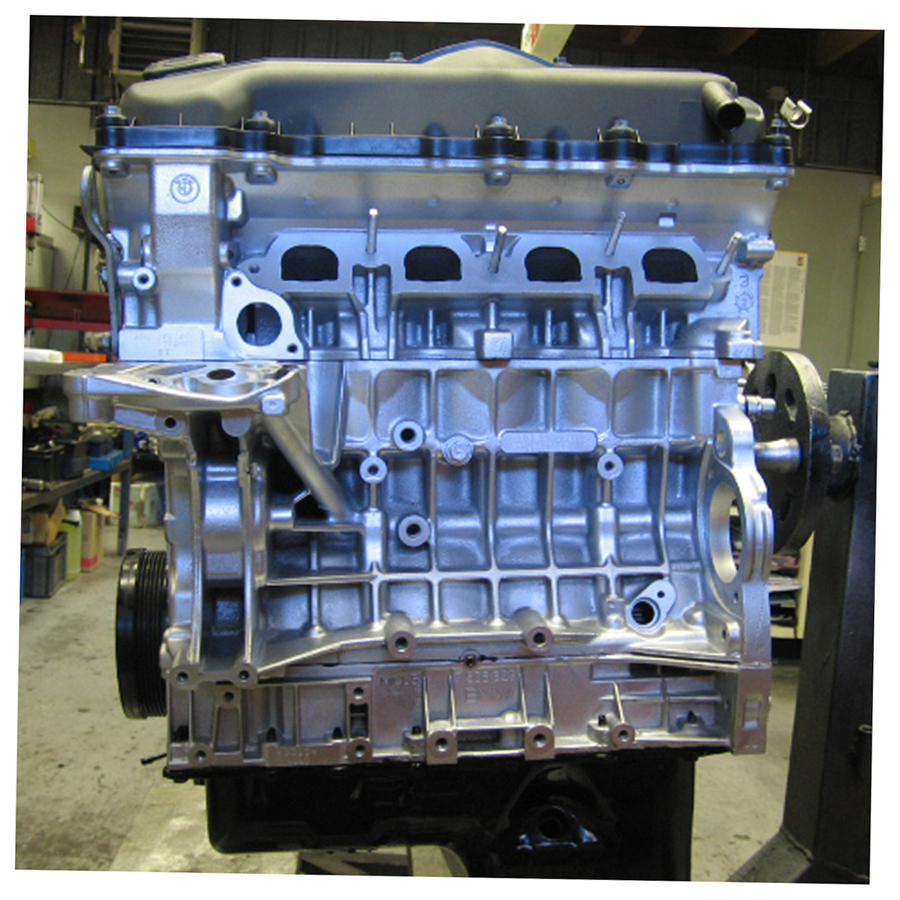

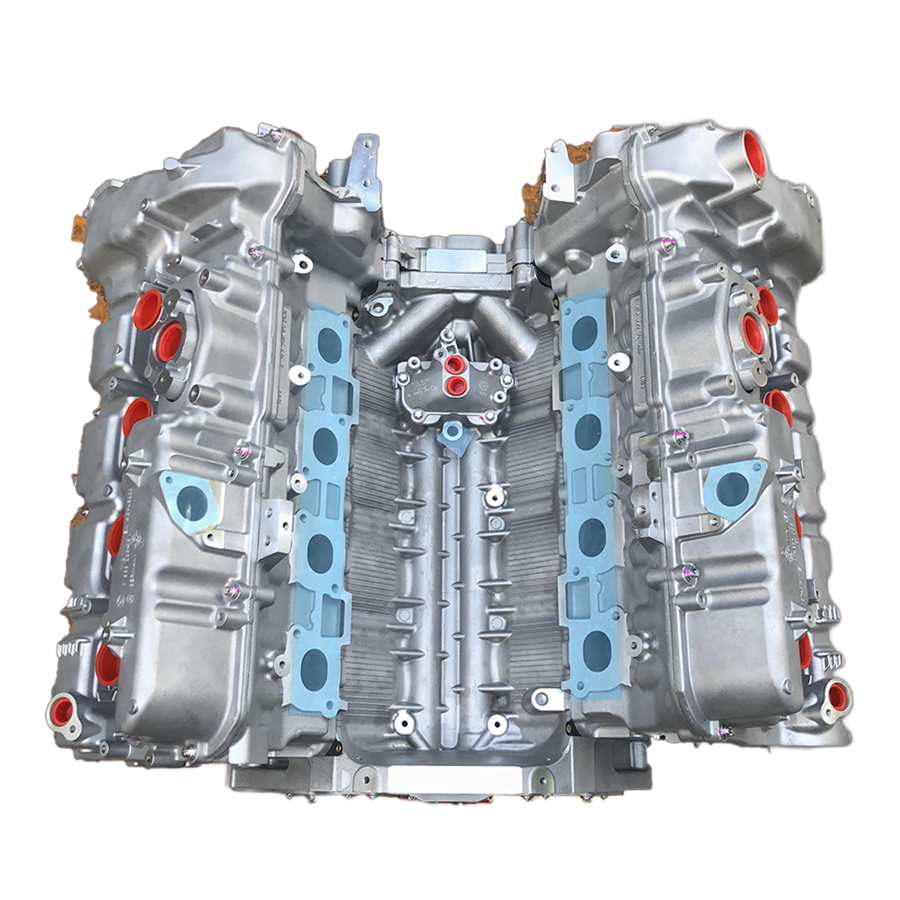

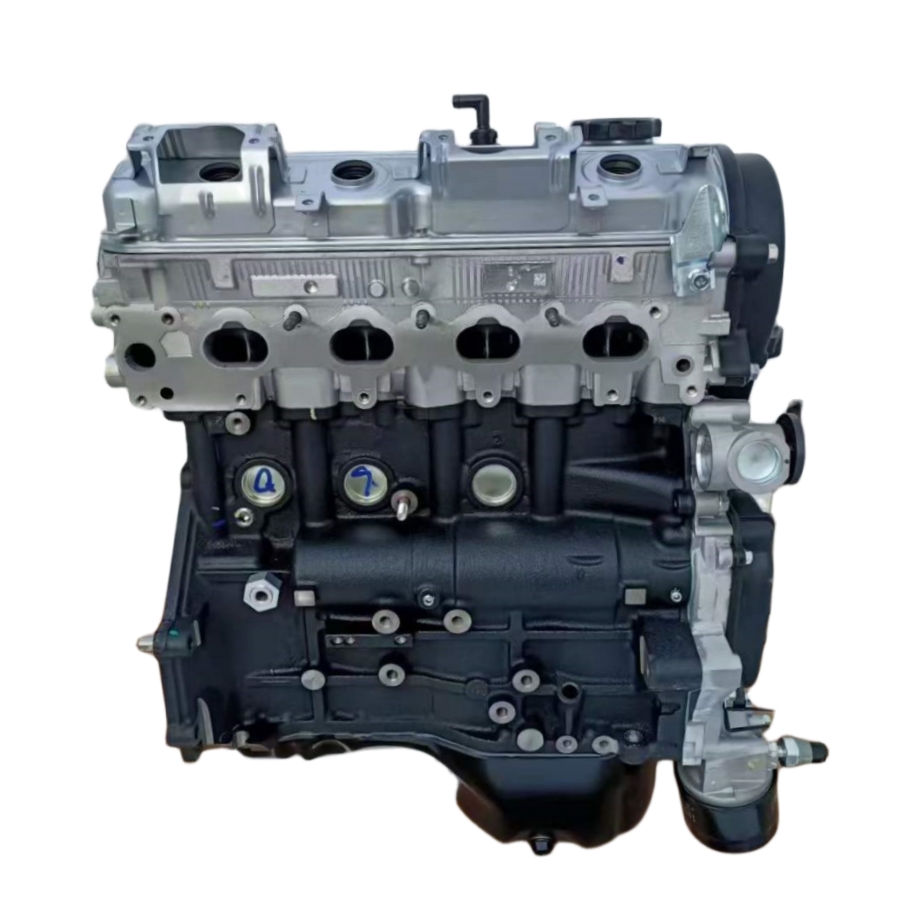

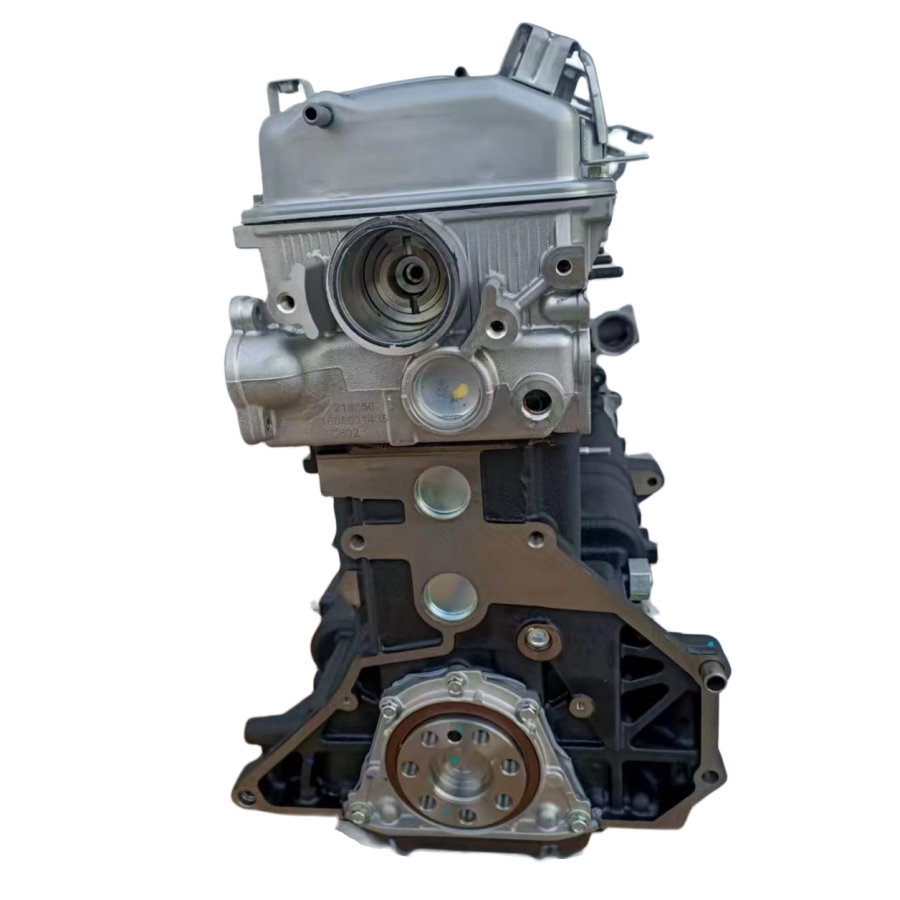

COMPLETE ENGINE : Engine Mitsubishi 4G63

PRODUCT INTRODUCTION

Specifications

Production years |

since 1981 |

Displacement, cc |

1997 |

Fuel system |

carburetor / single injection (4G63 SOHC 8V) |

Power output, hp |

87 – 110 (4G63 SOHC 8V) |

Torque output, Nm |

157 – 164 (4G63 SOHC 8V) |

Cylinder block |

cast iron R4 |

Block head |

aluminum 16v |

Cylinder bore, mm |

85 |

Piston stroke, mm |

88 |

Compression ratio |

8.6 – 9.0 (4G63 SOHC 8V) |

Features |

no |

Hydraulic lifters |

yes |

Timing drive |

belt |

Phase regulator |

no |

Turbocharging |

no (except for 4G63T, for which a separate article) |

Recommended engine oil |

5W-30 |

Engine oil capacity, liter |

4.0 |

Fuel type |

petrol |

Euro standards |

EURO 1 (4G63 SOHC 8V) |

Fuel consumption, L/100 km (for Mitsubishi Galant 1995) |

10.6 |

Engine lifespan, km |

~400 000 |

Weight, kg |

160 |